Accumulator

The primary purpose is indeed to minimize the transmission of oil pressure reactions within the clutch system. By doing so, it helps to ensure that the clutch pedal and the driver's feet experience reduced vibrations and excessive movement.

Automatic Disconnecting Differential

In part-time 4WD systems, a device disconnects the front differential from the drivetrain in 2WD mode, improving fuel efficiency and reducing wear. It engages when 4WD is selected, connecting the front differential and enabling power distribution to all four wheels.

Transfer Shift Actuator

The device enables switching the drive system from 2WD to 4WD in vehicles. It works with a transfer set and modifies the Operation Switch in the driver's seat of a 4WD pickup truck. This modification activates the actuator, which adjusts the sleeve clutch mechanism in the transfer set. This allows for propulsion mode adjustment between H2 (two-wheel drive), H4 (four-wheel drive high range), and L4 (four-wheel drive low range).

Clutch Release Cylinder

The main function is to receive oil pressure from the Clutch Master Cylinder when the clutch pedal is pressed. It increases the pressure to activate the clutch pressure plate, allowing the engine power to be disengaged while the vehicle is in gear.

Clutch Master Cylinder

The Clutch Master Cylinder is responsible for generating fluid pressure in the clutch system when the driver presses the clutch pedal to change gears.

Clutch Master Cylinder Sensor

The Clutch Master Cylinder Sensor is a vital component of the Clutch Master Cylinder, ensuring accurate and smooth clutch operation. It detects the position of the clutch pedal and monitors the fluid pressure in the clutch system. By sending signals to the vehicle's ECU, it enables the ECU to monitor and control the clutch operation with precision.

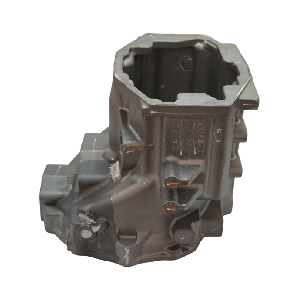

Case Clutch Housing

The Case Clutch Housing for agricultural tractors, which requires a large, complex hollow, is made possible by a unique core-making technique. Lifetime durability in heavy duty can be achieved with our iron casting expertise for big parts.

Transmission Set

A transmission unit made of aluminum casting and machining parts, produced using Medium and High-Pressure die-casting machines, incorporates a high level of technology applied from internal digital CAE design to achieve proper product validation. The process includes a high level of control over machining dimensions to ensure that our customers can assemble the parts correctly and be satisfied.

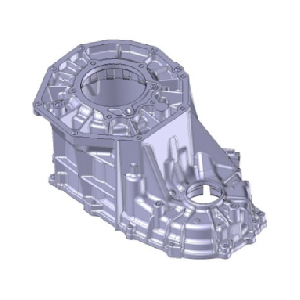

Transmission Case

The Transmission Case is a critical component that secures and houses aluminum parts in the transmission system. It is divided into three sections: the front Converter Housing enclosing the torque converter, the central transmission jacket for securing gear components, and the rear section with the rear gear adaptor for 4WD and housing extension for 2WD. These sections support the transmission shaft, ensuring proper operation.

Valve Body

The Valve Body is a device used to adjust oil pressure from the oil pump in order to match the requirements and change the oil flow path accordingly based on the running condition of the car. It also plays a crucial role in regulating the oil conditions to suit the clutch, brake, and torque mechanisms inside the automatic transmission (A/T).

Housing Extension

The Housing Extension is the part that assembles the rear of the transmission in a 2WD vehicle and is connected to the transmission axle.

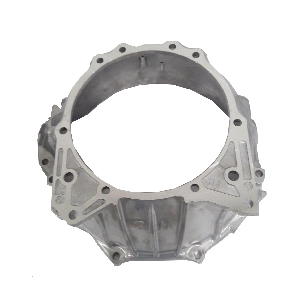

Housing Converter

The Housing Converter is the cover that acts as a torque converter part cover.

Adaptor

The Adaptor assembles the rear of the transmission in a 4WD vehicle and is connected to the transmission axle.

Transfer Case

The Transfer Case serves as the enclosure for the gear set responsible for transmitting power from the engine/transmission to the front wheels in a 4-wheel drive vehicle.

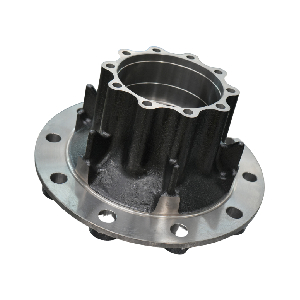

Hub

The wheel of a heavy-duty truck is supported by a large hub, which component is vital for both life and safety. As a result, we continuously enhance every step of our processes, from casting, machining as well as assembly to guarantee reliability and high quality.

Differential Case

The Differential Case is the housing for the gears responsible for distributing power to the wheels at different speeds during vehicle turns. Achieving precision in the machining process ensures a high level of customer satisfaction.

Differential Carrier

The differential Carrier is the housing for the differential module, which is a gear system that allows the left and right drive wheels to turn at different speeds while the vehicle is turning.

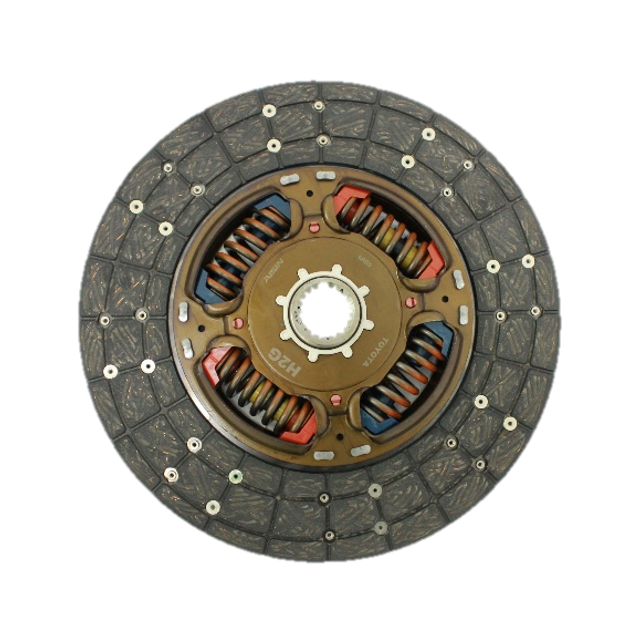

Clutch Disc

The Clutch disc transfers power between the engine and the transmission. When the clutch pedal is pressed, it separates from the flywheel, allowing gear changes and disengaging the engine power. When the clutch pedal is released, it makes contact with the flywheel, transferring power and enabling the vehicle to move forward.

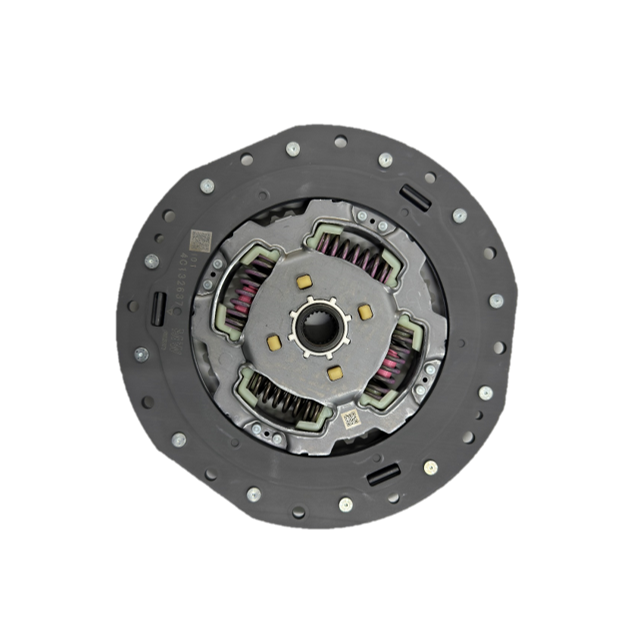

Clutch Cover

The Clutch Cover encloses and protects the clutch assembly, including the clutch disc, pressure plate, and release mechanism. It helps maintain the necessary pressure on the clutch disc and ensures smooth clutch engagement and disengagement when the driver operates the clutch pedal.

Dry Friction Facing

This dry friction facing is used in a manual transmission (MT) to transmit or shut off the power between the engine and MT at the starting, stopping or gear shifting. “Dry” is used in the product name because this friction facing does not require such oil.

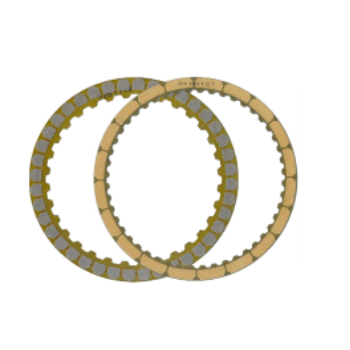

Wet Friction Material

Wet Friction Material is utilized in both automatic transmissions (AT) and continuously variable transmissions (CVT) to aid in gear-shifting control. It is composed of friction material that is firmly bonded to a steel ring for secure attachment.

Rear Pinion Gears

Rear Pinion Gears acts as planetary gears in an Automatic Transmission that is placed between the sun gear and the ring gear which enables transfer of rotation and power.

Hybrid Damper

Hybrid vehicle dampers are engineered to be lightweight yet durable to accommodate the unique characteristics of hybrid vehicles, which often have added weight due to the presence of electric components such as batteries and motors. They are also designed to work efficiently with hybrid powertrains, providing optimal performance while maximizing fuel efficiency and reducing emissions.